PRODUCTS

Fiberglass chopped strand mat powder binder

Fiberglass chopped strand mat, briefly as CSM, is a kind of reinforcing product that is made from fiberglass strand, which is chopped into a certain length, distributed in a random and non-directional positions and bonded with binders.

There are two types. One is chopped strand mat powder binder and another is chopped strand mat emulsion binder.

- It is suitable for hand lay-up, mould press, filament winding and mechanical forming etc, such as GRP process.

- The main products include kinds of panels, boats, sanitary ware, water tank, anti-corrosive engineering products, storage tank, automobile parts and cooling towers etc.

Product Features

- Uniform thickness, softness and hardness good.

- Good compatibility with resin, easy completely wet-out.

- Fast and consistent wet-out speed in resins and good manufacturability.

- Good mechanical properties, easy cutting.

- Good cover mould, suitable for modelling complex shapes.

Product Usage

The mats are compatible with unsaturated polyester, vinyl ester and other various resins. It’s mainly used in hand lay-up, filament winding and compression moulding processes. The typical FRP products are panels, tanks, boats, complete set of sanitary equipment, automotive parts, cooling towers, pipes etc.

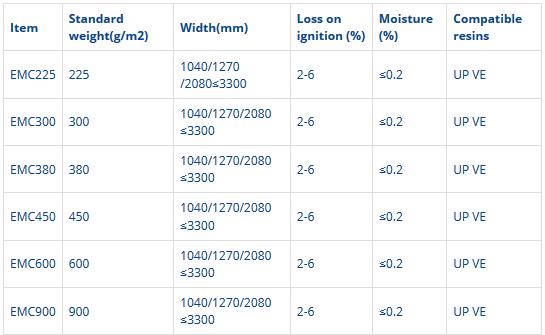

Specification

Fibreglass chopped strand mat emulsion binder

E glass emulsion Chopped Strand Mat (CSM) is produced by chopping glass fiber strands or roving in lengths of about 50mm and upon depositing these at random in a horizontal plane, they are adhered together in a mat with polyester emulsion binder. CSM is mainly used in glass fiber reinforce plastics(FRP) winding process, such as hand lay-up molding, compression molding, centrifugal casting molding, machine molding and so on.

Product Application :

Can be widely used in automobile accessories, sanitary ware, chemical anticorrosive pipe, cooling tower, storage tank, the ships, the construction component, furniture and all kinds of glass fiber reinforced plastic(FRP) products.

Fiberglass Roving

Glass type is E glass non-twist fiberglass roving. Fiberglass roving as per the technical, there are direct/single-end and assembled /multi-end, two kinds of fiberglass roving.

Fiberglass roving as per the different application, there are filament winding roving, smc roving, csm roving, spray up roving, pultrusion roving, weaving roving, chopped roving, thermoplastics roving, panel roving, lft roving. Linear densities have 300tex, 600tex, 900tex, 1200tex, 2400tex, 4800tex, 9600tex.

Fiberglass Direct Roving

E-glass direct rovings: Direct roving for filament winding, Direct roving for pultrusion, Direct roving for weaving, Direct roving for LFT and etc.

Fiberglass Assembled Roving

E-glass assembled rovings: Assembled for spray up, Assembled roving for filament winding, Assembled roving for SMC, Assembled roving for chopping, Assembled roving for centrifugal casting, Assembled panel roving, Assembled roving for thermoplastics, Assembled roving for GMT and etc.

Applications:

Fiberglass roving is widely used in fields like automotive, vessels, gratings, bathtub, FRP composite, tanks, waterproof, reinforcement, insulation, spraying, spray gun, mat, gmt, boat, csm, frp, panel ,car body, knitting, chopped strand, pipe, gypsum mould, boat hulls, wind energy, wind blades, fiberglass boat hulls, boats fiberglass, fiberglass pools, fiberglass fish tank, fiberglass fishing boat, fiberglass moulds, fiberglass rods, fiberglass swimming pool, fiberglass boats moulds, fiberglass pool, fiberglass chopper gun, fiberglass spray gun, fiberglass water tank, fiberglass pressure vessel, fiberglass poles, fiberglass fish pond, fiberglass resin, fiberglass car body, fiberglass panels, fiberglass ladder, fiberglass insulation, fiberglass dinghy, fiberglass car roof top tent, fiberglass statue, fiberglass grating, fiberglass rebar, glass fiber reinforced concrete, fiber glass swimming pool and etc.

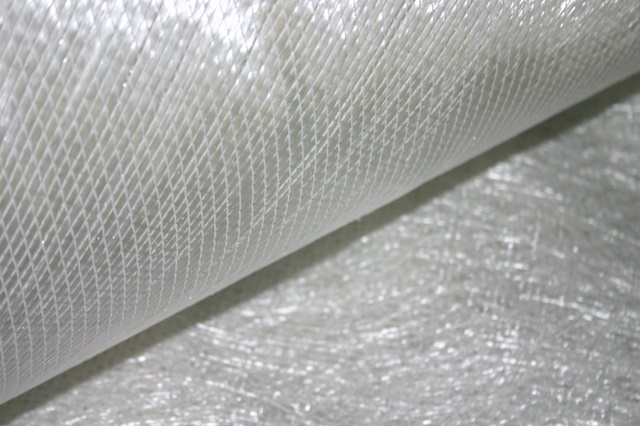

E-Glass Woven Roving mat

E-Glass Woven Roving are bidirectional fabric made by interweaving roving and compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins. They are used for hand lay-up and robot automation process of FRP products such as boats, vessels, automotive parts and architectural structure etc.

Product Properties:

- Warp and weft roving aligned in a parallel and flat manner, resulting in uniform tension.

- Densely aligned fibers, resulting in high dimensional stability and making handing easy.

- Good mold ability, fast and complete wet in resins, resulting in high productivity.

- Good transparency and high strength of composite products.

Fiberglass Surface mat/tissue

Fiberglass surface tissue is characterized as uniform fiber dispersion, smooth surface and fast resin impregnation. It is mainly used in surface layer of FRP products of which the capability is ameliorated.

It is capable if significantly improving the strength of FRP surface layer, strong resistance, excellent uniformity of surface, good covering up the texture of under layers and good corrosion resistance.

Fiberglass surface tissue can satisfy the different process requirements of hand lay-up, cement winding and pull trussing, serving for customers and guaranteeing good quality for the later products.

Application:

Surfacing mat is mainly used in the surface layers of FRP products. Surfacing Tissue are mainly used on pipe and tank winding process. It can improve the product surface property on corrosion resistance, comprehensive strength, seepage resistance, and longer service life.

Specification:

- Weight/m2: 30g-120g/m2

- Length: 25m-200m;

- Width: 1m/1.25m

- Color: White (standard) other colors;

- Packing: Each roll packed into plastic bag, then it is placed inside a carton box;

- Special specification and package can be ordered and produced according to customers requirement.

- Area Weight:30g/m2,40g/m2,50g/m2,90g/m2, 120g/m2 and so on.

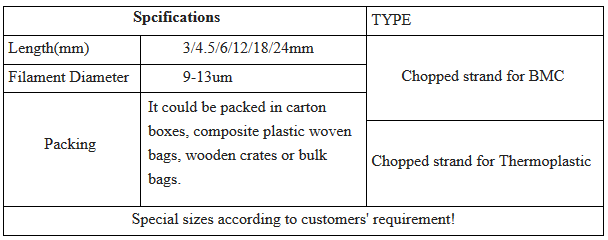

Fibreglass Chopped strands

We have two kinds of Chopped Strands: E-Glass Chopped Strands for BMC and E-Glass Chopped Strands for Thermoplastics.

E-glass Chopped Strands for BMC

Product Features:

- Fast wet-out resins

- Low fuzz

- Good mold flow ability

- High fiber integrity

- Excellent mechanical properties

- Distinct white color

Product Application:

E-Glass Chopped Strands for BMC are widely used in transportation, construction, electronics, chemical industry and light industry, such as the automotive parts, insulator, and switch boxes.

E-glass Chopped Strands for Thermoplastics

Chopped Strands for Thermoplastic are designed for PP,PA,AS/ABS,PET, PBTPOM,PPS and PC.

Product Features:

- Silane-based coupling agent which delivers most balanced sizing properties.

- Special sizing formulation which delivers good bonding between chopped strands and matrix resin.

- Excellent integrity and dry flow ability, good mold ability and dispersion.

- Excellent mechanical properties and surface condition of composite products.

Product Application:

E-Glass Chopped Strands for Thermoplastic are mainly used in injection and compression molding processes and its typical end-use applications include automotive industry, home appliances,valves,pump housings,chemical corrosion resistance and sports apparatus.

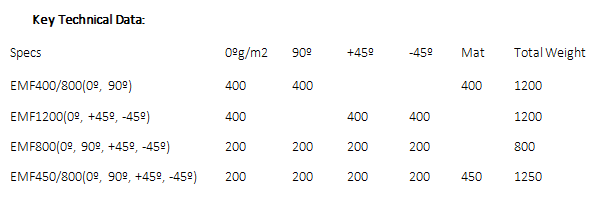

Biaxial fabric/sticth mat/combo mat

E-Glass multiaxial fibreglass fabric is made of e-glass direct roving parallel aligned in 0º,90º, +45º, -45º, then stitched with or without a layer of chopped strand mat.

Each layer is typically oriented in one of four directions; Standard configurations offered by multiaxial fabric suppliers include biaxial(0º, 90º), double bias(+45º, -45º), triaxial warp(0º, +45º, -45º), triaxial weft(90º, +45º, -45º) and four axial (0º, 90º, +45º, -45º).

It’s compatible with UP, Vinyl Ester and Epoxy etc, used in GRP pultrusion process, hand lay-up process and RTM process etc, out-made products include GRP boats, automobile parts, wind energy blades etc.

Products Feature & Advantages :

- Mechanical property of different directions is adjustable.

- The multi-layers structure could simplify forming process, improve operation efficiency.

- Quickly wet-out, good molding property, easily to delete air bubbles.

Packing:

E-Glass Multiaxial fibreglass fabrics wound onto a paper tube which has an Inside diameter of 90mm. The roll outside diameter is approximately 265mm. Each roll is wrapped up in plastic film and then packed in a cardboard box. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.

Fiberglass Mesh Fabric

Fiberglass Mesh Fabric- Fiberglass Mesh is based on the alkaline fiber-glass woven fabric and finished after being coated with an organic material. It is made of fiberglass yarn or roving by means of leno or plain weave. The material used for coating ensures excellent resistance to chemical substances and increases mechanical durability that is required by the construction industry.

Types- 45gsm, 80gsm, 145gsm

Features:

- Alkali resistance

- Perfect finish

- Application-specific

Application Areas:

- It is widely used as reinforcement for waterproofing of terrace, bathroom, basement etc

- It is also used as reinforcement for stone processing industries as it easily sticks on the back of the marble, mosaic and stone and offers great strength because of its balance structure.

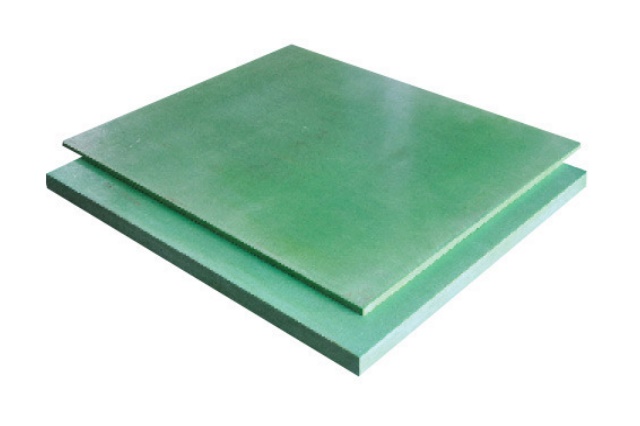

Fibreglass sheets

We are engaged in offering a wide range of fiber glass products. Among these we offer Fibreglass Sheet. These are made up of high quality fabric and are highly demanded. These sheets are available in different specifications and sizes, as per the diverse requirements of clients.

Features:

- High dielectric strength at high humidity

- Excellent mechanical & thermal properties

- Minimal maintenance

- Available all the sizes

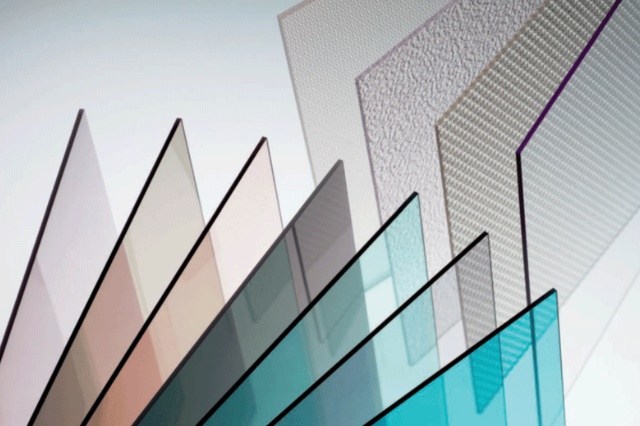

Polycarbonate sheets

Offered sheet is available in various dimensions & other related specifications to choose from. This sheet is well checked on diverse parameters in order to supply a defect free range. The sheet provided by us is manufactured from the top in class material & techniques.

The properties like UV-resistant, weather-resistant, high impact resistance, excellent light transmission, high heat-resistant, wide color range, lightweight, availability in large sizes, flame-retardant make it a preferred product for innovative applications across the range of manufacturing and business sectors including electrical and electronics, aerospace, transportation, building and construction, telecommunications, machines industries, material handling industry etc.

Features:

- High strength

- Long working life

- Easy to install

Pet Preform

PET bottles are a huge market for the material. In the first step, PET is injection molded into a "mini bottle," complete with threads, called a preform. ... This preform is then reheated, stretched and blown into its final shape.

A preform is an intermediate product that is subsequently blown into a polyethylene terephthalate (PET) container. Preforms vary in neck finish, weight, colour and shape, and are specifically designed to meet the needs of customers in different market segments.